The 10-Minute Rule for Inventory Management

Get This Report on Inventory Management

Table of ContentsFacts About Inventory Management UncoveredWhat Does Inventory Management Do?The 6-Second Trick For Inventory ManagementThe Basic Principles Of Inventory Management The Facts About Inventory Management Revealed

The routine supply system is a technique of supply assessment for monetary reporting objectives in which a physical matter of the supply is performed at particular periods. This audit technique takes stock at the beginning of a period, includes new supply acquisitions during the period as well as subtracts finishing supply to derive the price of goods marketed (GEARS).They can associate a number of information points to the number, consisting of the supplier, item dimensions, weight, and also also variable data, such as how lots of remain in stock. RFID or superhigh frequency identification is a system that wirelessly sends the identity of an item in the form of an one-of-a-kind serial number to track items and offer detailed product info.

The Ultimate Guide To Inventory Management

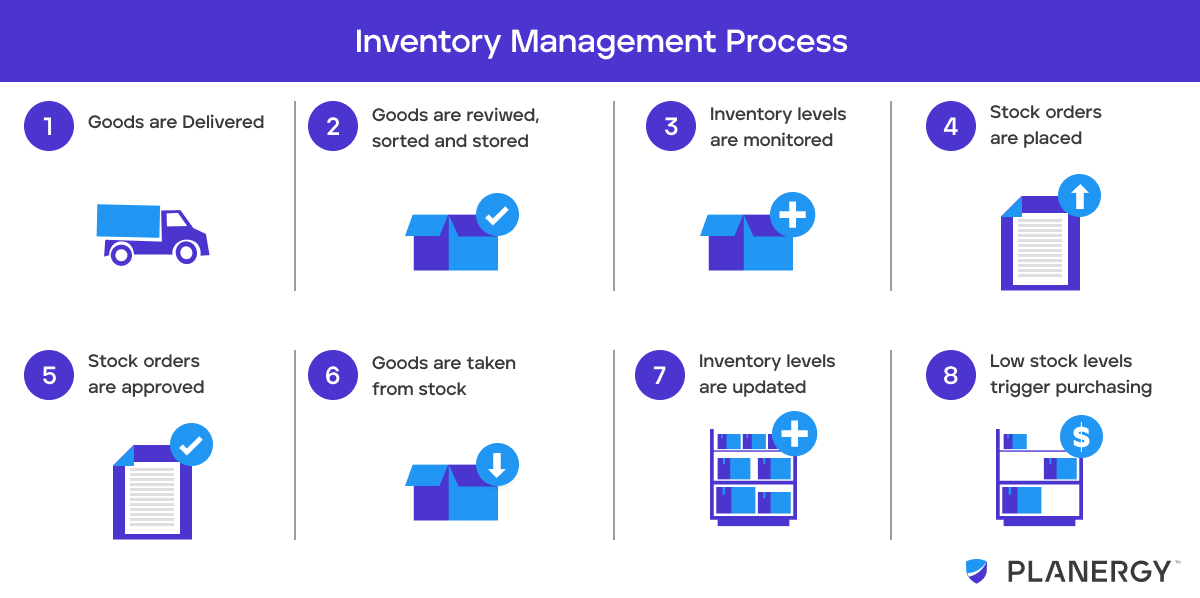

Stock management refers to the procedure of saving, buying, and also marketing of goods and services. One of the most crucial elements of supply administration is taking care of the flow of raw products from their purchase to finished items.

As an example, an oil depot can store a huge inventory for a long period of time. Or for organizations that handle perishable products, such as fast-fashion products, keeping top of your supply can be very expensive. One means to represent supply is by grouping it into four categories: first-in-first-out, last-in-first-out, weighted-average, as well as first-in-first-out.

Depending on the kind of business that it is dealing with, various supply management methods are utilized. Some of these consist of JIT, product need preparation, and days sales of stock.

A Biased View of Inventory Management

Discover also a lot more regarding stock administration from Walton University's Supply Chain Administration program's introduction on the subject covering everything from projecting to aim versions: One of the most valuable possessions of a firm is its supply. Inventory Management. In numerous markets, such as retail, food services, as well as production, an absence of stock can have damaging effects.

It can be susceptible to burglary, damage, and also putridity. Having a large inventory can also bring about a reduction in sales. Both for small companies and also huge corporations, having a correct supply administration system is very crucial for any service. It can help you maintain track of all your materials and also establish the precise prices.

This is especially important for brands wanting to come to be an extra customer-centric organization. Stabilizing the risks of overstocks and also scarcities is a particularly tough procedure for companies with complicated supply chains. A firm's inventory is typically a current possession that it intends to market within a year. Inventory Management. It should be measured and also counted on a regular basis to be considered an existing property.

Getting My Inventory Management To Work

Not just will it serve to enhance performance, however it's likewise valuable for preventing burglary with the help of item monitoring and also safety and security. Managers can additionally intend to use their supply administration plan to monitor sales treatments which leads to better solution.

Giving customers numerous different kinds of internationally-grown produce in both organic and also non-organic selections at a cost effective rate, also when the fruits as well as vegetables aren't in season, is a modern marvel many thanks partly to stock monitoring. Overseeing supply in real time and also even setting up automated replenishment systems is mission-critical to lots of.

Inventory Management Fundamentals Explained

6 million packages from their brand to third-party sellers each day. Their Smart Stockroom makes use of robot and also human aid to finish the job, yet it's supply monitoring that maintains all of it rolling. According to Tech Vision, "Amazon's administration method, together with all that automation, have made the service tremendously lean and also mean by historical requirements." The stock monitoring of toilet tissue firms remained in the hot spot in very early 2020 as panic-buying resulted in lacks nationwide.

Here are the main types you should know: Basic material, This refers to pieces of your product that demand to be shipped to you and put together by your team. Supply systems that track these should account for provider timelines. Underway, Products made from raw materials and are presently being assembled or grouped fall under this group.